3D printing is a manufacturing method that creates objects by depositing material layer by layer, and this process gives electronics builders a level of customization that traditional fabrication often cannot match. Interest in additive manufacturing has surged as more hobbyists and professionals adopt rapid prototyping to speed up development and reduce cost. The ability to design enclosures, brackets, robot bodies, mounts, and wire-management structures that fit components perfectly has changed how projects are conceived and built. This guide explores which materials perform best, how printing technologies differ, how to strengthen designs, how much various methods cost, and how printed components compare with machining and cutting alternatives. By the end, you will understand how to design and produce electronics parts that are stronger, cleaner, and more reliable.

3D printing enables designers to create shapes that meet their exact assembly requirements. Electronics often consist of boards, connectors, sensors, batteries, and modules that rarely share standard dimensions. With additive manufacturing, parts can adapt to your components rather than forcing you to adjust the electronics to off-the-shelf housings. This flexibility becomes even more valuable in robotics, where frames must withstand dynamic loads while remaining lightweight. Another advantage is the speed at which prototypes evolve. Changing the placement of standoffs, shifting ventilation slots, resizing a hinge, or reinforcing a bracket can be done within minutes and printed within hours. This reduces the friction between design and testing and improves the reliability of the final build.

• Custom-fitted housings

• Lightweight but rigid robot frames

• Integrated wire channels

• Dampened vibration mounts

• FPV camera and sensor brackets

• Test fixtures and jigs

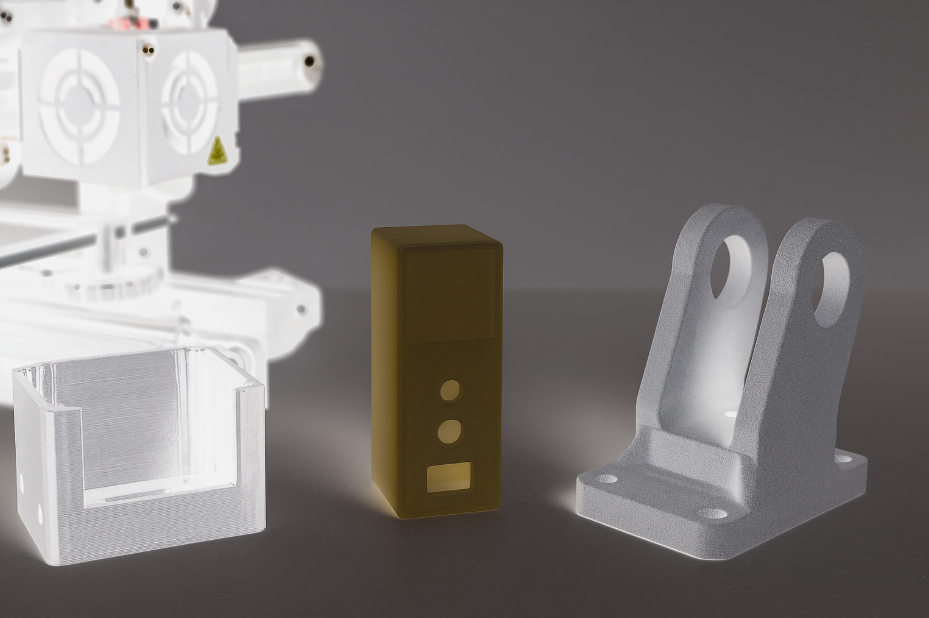

3D printing materials are polymers that determine how a printed part behaves under load, temperature, or vibration. Choosing the right material directly affects electronic performance. PLA is stiff and accurate, making it suitable for indoor enclosures. PETG absorbs impact and tolerates moderate heat, which helps when parts sit near motors or regulators. ABS withstands vibration and elevated temperatures, making it useful for robot arms and drivetrain housings. ASA adds UV resistance. Nylon delivers impressive toughness and flexibility for gears or linkage components. Polycarbonate supports heavy loads and resists cracking in structural applications.

• PLA

• PETG

• ABS

• ASA

• Nylon

• Polycarbonate

These materials differ in strength, heat resistance, and durability, and those differences determine which material performs best in specific electronics environments.

PropertyPLAPETGABS

Strength Medium High High

Heat Resistance Low Medium High

Ease of Printing Very easy Easy Moderate

Best Use Enclosures, Structural housings, Robot components

3D printing technologies are groups of processes that shape material into functional components, and each method provides distinct benefits for electronics builders. FDM is accessible and works well for most structural parts. SLA offers excellent details and smooth surfaces. SLS produces durable nylon components with uniform strength.

FDM is a technology that extrudes melted filament to form layers, and this method is widely used for enclosures, robot brackets, and structural frames. It supports strong walls, reinforced mounting points, and customizable infill settings that influence rigidity.

• Frames

• Brackets

• Enclosures

• Functional prototypes

SLA is a technology that cures liquid resin with light to create fine, detailed parts, making it ideal for compact housings, precision faceplates, small connectors, and tight-tolerance features in electronic assemblies.

• Small enclosures

• Precision connectors

• Polished faceplates

• Micro mounting components

SLS is a technology that sinters powdered nylon into solid parts, and this method excels in durability, abrasion resistance, and geometric freedom. It is beneficial for robot limbs, clamps, gears, and heavily loaded brackets.

• Robot limbs

• Mechanical gears

• Impact-resistant housings

• Structural supports

Strong 3D-printed parts result from understanding how materials behave, how forces propagate through the design, and how layers bond. Electronics components often experience heat from regulators, torque from motors, stress from screws, and vibration from movement. Structurally sound designs consider how each feature contributes to durability. Internal ribs add stiffness without adding significant weight. Fillets reduce stress concentrations. Mounting holes backed by thicker walls prevent cracking. Wire channels keep cables from pulling against important structural areas. Thermal openings prevent overheating while preserving rigidity.

The right material is the one that supports your mechanical and thermal requirements. PLA is suitable for indoor projects with stable temperatures. PETG tolerates mild heat and flexing. ABS handles vibration and higher temperatures. Nylon and polycarbonate support heavily stressed components.

Layer orientation determines whether a part withstands bending or fractures prematurely. Layers resist tension best when oriented perpendicular to the direction of stress. This matters in hinges, robot arms, or structural beams that carry directional loads.

Reinforcement improves durability by thickening weak areas and distributing forces more evenly. Rounded corners prevent crack initiation. Ribs add stiffness. Mounting tabs should include additional material to prevent failure when fasteners are tightened.

• Add ribs

• Add fillets

• Thicken mounting walls

• Reinforce hole areas

Electronics need secure mounting locations and clean cable routing. Adding screw bosses, snap fits, or clip designs helps components stay in place. Channels guide wires safely and prevent abrasion.

Assembly becomes easier when parts include indexed edges, snap features, hinges, and well-sized bosses. Tolerances must account for slight variations in printer performance to ensure parts connect reliably.

Reducing failures involves optimizing adhesion, calibrating supports, leveling the build surface, and designing with overhangs and bridging in mind.

• Improve adhesion

• Adjust cooling

• Optimize supports

• Reduce steep overhangs

3D printing offers benefits such as customization, rapid iteration, cost efficiency, and weight reduction. It also allows designers to create shapes that are impossible to machine and to adjust part strength by modifying internal structure.

• Custom fit parts

• Fast revisions

• Lower cost

• Lightweight builds

• Tunable strength

• Complex geometry

• Niche adaptations

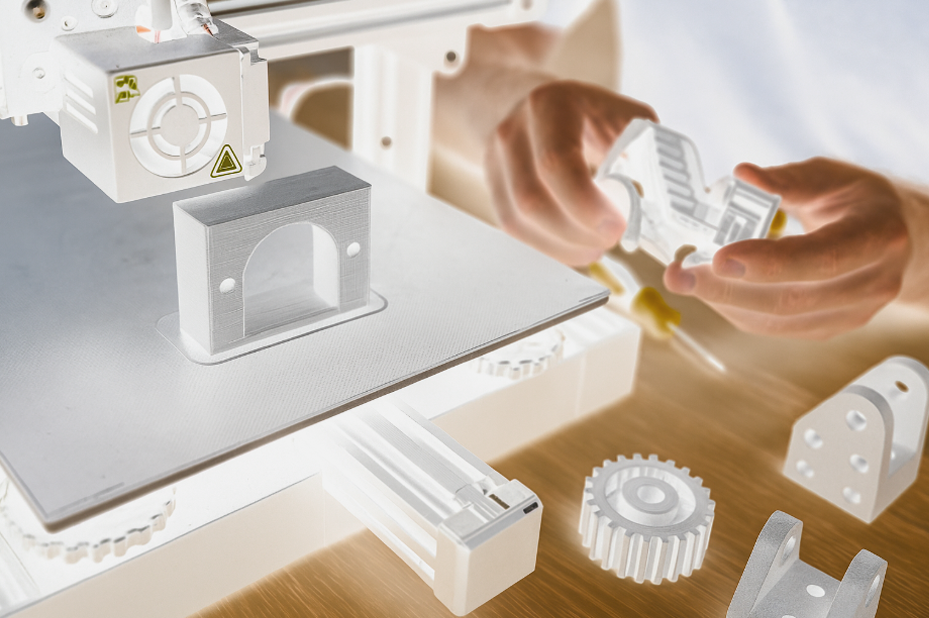

Many engineering teams choose industrial 3D printers to produce durable electronics housings and robotic components with consistent accuracy.

3D printing has limitations involving heat sensitivity, dimensional accuracy, vibration fatigue, and material conductivity. Polymer-based parts soften at high temperatures and may deform under heavy loads.

• Heat sensitivity

• Warping

• Limited conductivity

• Fatigue over time

• Dimensional deviation

• Size limitations

Durable prints emerge from careful calibration and design. Preparing the printer, choosing suitable materials, orienting layers correctly, adjusting infill, reinforcing stress points, and testing prototypes all improve reliability. A consistent workflow helps developers refine each iteration until the part behaves correctly.

Costs vary based on material type, printer technology, part volume, and finishing requirements. FDM prints are inexpensive, while SLA and SLS prints cost more due to the properties of the resins and powders used.

• Material

• Volume

• Technology

• Post processing

• Print duration

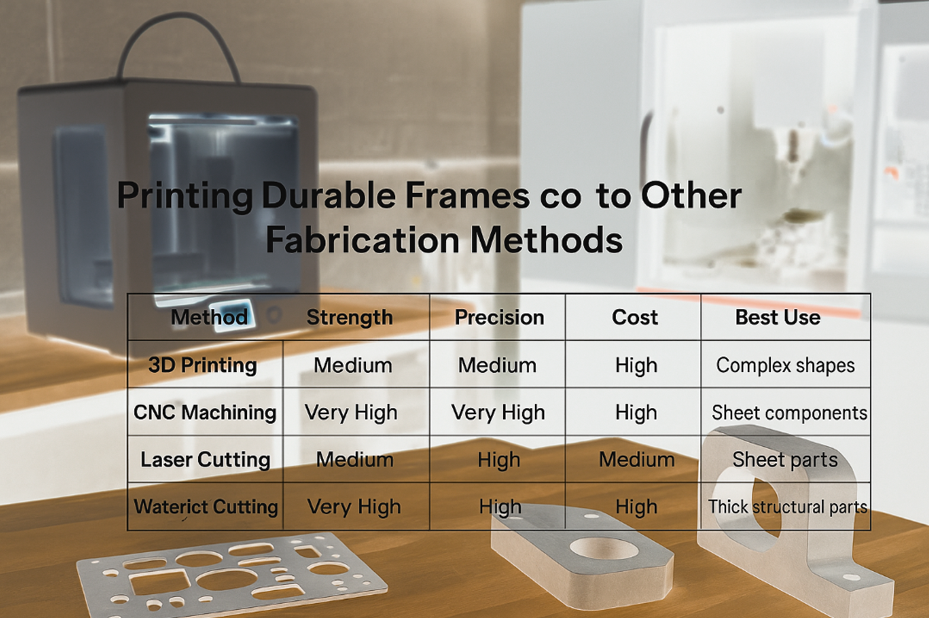

When deciding whether plastic parts can withstand required loads, designers sometimes compare them to components made with Waterjet cutting technology, which delivers high-strength results for metal-based builds.

TechnologyTypical CostMaterialStrength

FDM Low PLA, PETG, ABS Medium

SLA Medium Resins Medium High

SLS High Nylon High

Electronics builders use 3D printing for enclosures, robot limbs, FPV mounts, PCB holders, sensor housings, test fixtures, and cable management systems. These parts support functionality, improve ergonomics, and protect components from damage.

• Enclosures

• Robot frames

• FPV parts

• PCB holders

• Sensor housings

• Wire channels

• Test fixtures

3D printing competes with machining, laser cutting, and waterjet cutting. Machining offers metal strength and tighter tolerances. Laser cutting handles sheet materials quickly. Waterjet cutting is well-suited to thick, strong materials. Each method serves a different structural role.

Method Strength Precision Cost Best Use

3D Printing Medium Medium High Low Complex shapes

CNC Machining Very High Very High High Metal components

Laser Cutting Medium High Medium Sheet parts

Waterjet Cutting Very High High High Thick structural parts

Several factors affect the reliability of printed electronics. Thin walls crack, poor ventilation causes heat buildup, incorrect tolerances lead to assembly problems, and mounting points fail when aligned with weak layer directions. Designers who understand these pitfalls produce stronger and safer builds.

• Thin walls

• No ventilation

• Incorrect tolerances

• Weak mounting tabs

• Poor orientation

• Sharp corners

Some teams compare their printed designs with metal equivalents produced via CNC laser cutting to understand structural behavior better and improve component durability.

3D printing enables electronics designers to design and fabricate parts that fit their projects precisely. Strong frames, clean enclosures, and reliable robotic mechanisms all benefit from selecting the right material, properly orienting layers, and reinforcing stress zones. When paired with thoughtful design and complementary fabrication technologies, additive manufacturing becomes a powerful tool for developing innovative electronics systems that function reliably in real-world environments.