3D-printed enclosures are housings that protect and organize the electronics in your DIY project.

A breadboard demo can work on a desk, but it will fail the first time you carry it or set it near metal tools.

Because every board layout and connector choice changes the shape you need, the 3D printing process fits DIY electronics.

A 3D printed enclosure is a protective shell that houses electronic components and controls access to them.

It matters because exposed circuits are easy to short and easy to damage.

In many builds, the weak points are mechanical.

Ports flex, batteries rattle, and switches get pressed sideways.

A good enclosure solves those problems with standoffs, openings, and strain relief that match your exact layout.

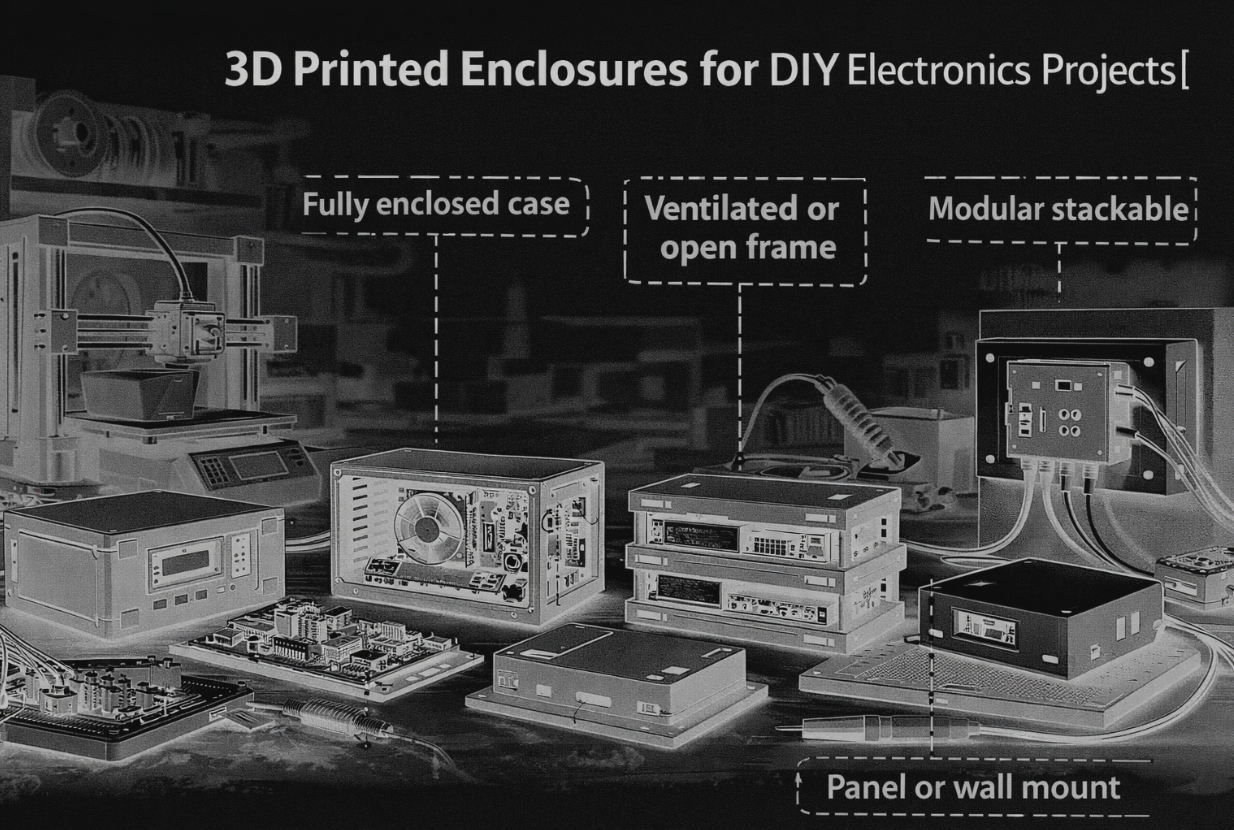

Electronics enclosure types are categories of case designs that group similar structures and protection levels.

The main types include fully enclosed cases, ventilated or open frame designs, modular stackable systems, and mount-ready housings for panels or walls.

Pick the type by starting with environment, then heat, then access.

A motor driver needs airflow that a sensor node does not.

A prototype you tweak daily needs easier access than a device you want sealed.

If you open the device often, prioritize designs that tolerate repeated assembly.

If the project must meet a real safety expectation, treat enclosure choice as part of risk control, not decoration.

Here are four enclosure types and where each fits.

Fully enclosed case: portable devices and messy environments

Ventilated or open frame: hot components and frequent testing

Modular stackable: projects that will expand over time

Panel or wall mount: fixed installs with tidy cable exits

3D printing technologies are manufacturing methods that build parts layer by layer from a digital model, shaping strength, detail, and surface finish.

For enclosures, most makers choose between FDM 3D printing and resin printing.

Filament printing is usually the best start for boxes, brackets, and lids.

Resin printing is useful when buttons, labels, and cutouts must look crisp.

FDM 3D printing is a process that extrudes melted filament through a nozzle and deposits it in layers to form the part.

It is popular for DIY enclosures because it is affordable and easy to iterate.

Print orientation and screw boss design matter more than ultra-fine layers.

If you are evaluating machines for enclosure work, a clear 3D printer buying guide helps you match build volume, material support, and reliability to real projects.

SLA 3D printing uses light to cure liquid resin into solid layers, whereas DLP cures a whole layer at once.

This 3D printing technology creates sharp edges for buttons, text, and display windows.

Resin parts can look finished fast, but many resins are less impact-tolerant than filament parts.

If you are doing DLP vs SLA 3D printing comparisons, treat both as detailed first options and design thicker tabs and ribs to reduce cracking.

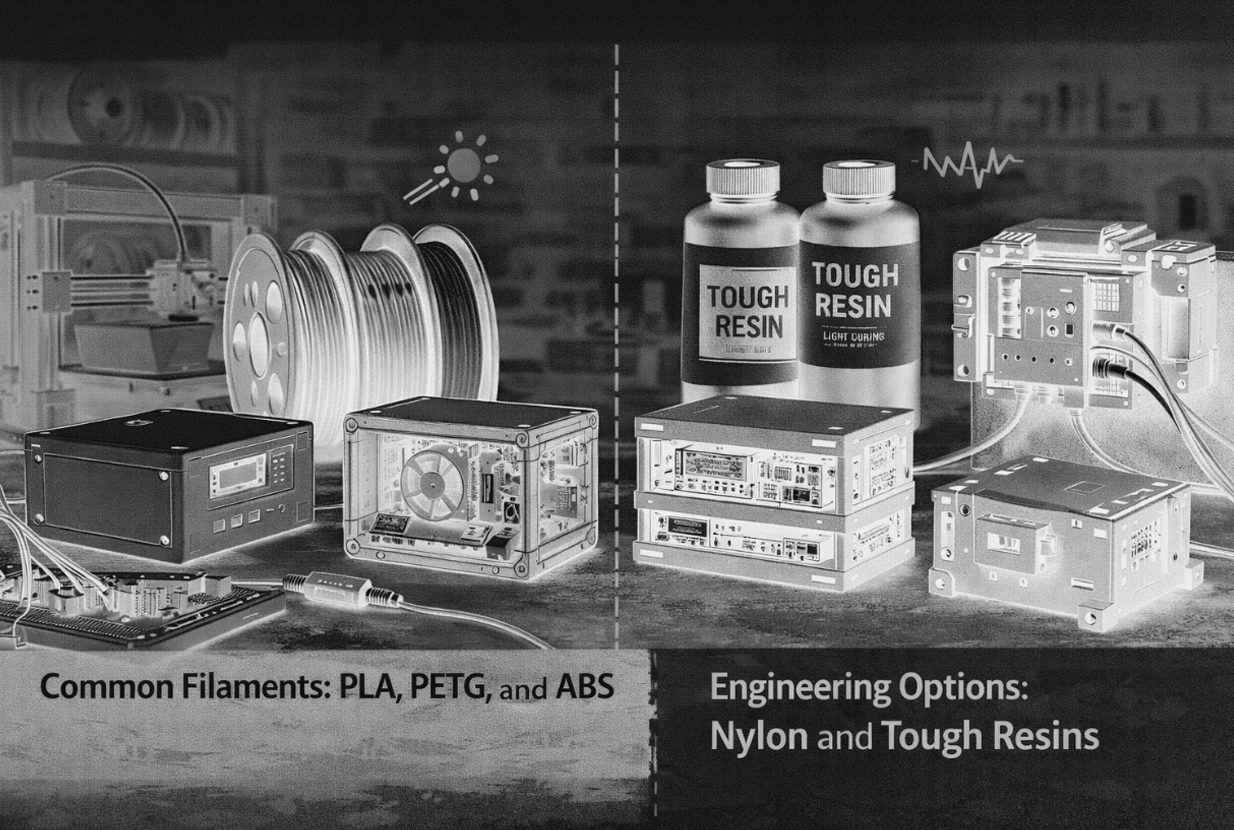

3D printing materials are plastics or resins that form the enclosure, and they determine heat resistance and toughness.

Common choices include PLA, PETG, ABS, and nylon.

A case near regulators, drivers, or sunlight needs better temperature tolerance.

PLA is a rigid filament that prints easily and fits cool indoor gadgets.

PETG is tougher and more moisture-tolerant, which makes it a strong general choice for cases with cable movement.

ABS handles higher temperatures, but it prefers a controlled print setup to reduce warping.

When you are unsure, start with PETG, then move to ABS when heat becomes the limiting factor.

Nylon is a tough plastic that withstands repeated flexing and wear, making it useful for rugged clips and machine-mounted enclosures.

Tough resins can work for small, detailed parts, but you should validate impact strength before relying on thin tabs.

If your device is exposed to vibration, these materials can help prevent cracks that appear after weeks of use.

The key design factors are fit, access, heat management, and mechanical retention, because they determine whether the enclosure protects the electronics without making the device difficult to use.

Start with real measurements of the PCB, connector housings, and cable bend radii, not just the board outline.

Most fit issues come from tiny oversights.

A USB plug needs room for the molded strain relief.

A battery needs a removal path that does not snag wires.

Heat needs attention, too, because warm air trapped in a small box changes the component life.

When in doubt, prototype the tight areas first, such as ports and lids, before you print the full case.

Use this checklist before you commit.

Component clearance for tall parts and cable bends

Port and button access for real plugs and real hands

Airflow for heat-producing modules

Fastening strategy, including inserts for repeat opening

Environmental exposure, including dust and static risk

3D printed enclosures deliver customization, protection, and faster iteration than most off-the-shelf options.

They let the shape follow your PCB and workflow, rather than forcing compromises.

The advantage is not only cosmetic.

A better enclosure reduces strain on solder joints and keeps connectors aligned.

It also makes testing less stressful, because you can open and close the device without wires popping off.

Done right, it saves time.

It also makes your project easier to share, because a case invites handling without fear.

And it helps upgrades, because you can design in access panels from day one.

Here are six advantages, ordered from common to specific.

Enable customization for ports, standoffs, and odd board shapes

Improve protection from touch, dust, and accidental shorts

Speed up iteration when the first design needs revisions

Reduce cost for one-off and small batch housings

Enhance usability with ergonomic controls and labeling

Support special form factors like wearables and curved mounts

3D-printed enclosures can suffer from weaker layer bonding, heat limits in some plastics, and dimensional variation if printing is not properly tuned.

These drawbacks affect wall thickness, fastener selection, and vent placement.

Flat lids can warp and fail to seal.

Thin clips can fatigue after repeated flexing.

Port openings can shrink slightly depending on the material and cooling.

Small tolerances can also stack up, so a perfect CAD fit can become a tight real fit.

Material aging is another factor, because some plastics creep under load and some resins embrittle over time.

If you plan for that, you will choose thicker features and smarter fasteners.

Here are six limitations to plan around.

Reduce the strength between layers if parts are oriented poorly

Increase warping on large flat panels in shrink-prone plastics

Limit heat resistance near hot components in low-temperature materials

Create rough openings if stringing, and blobs are not tuned

Strip threads if screws are over-tightened in plain plastic

Invite debris through vents if shields are ignored

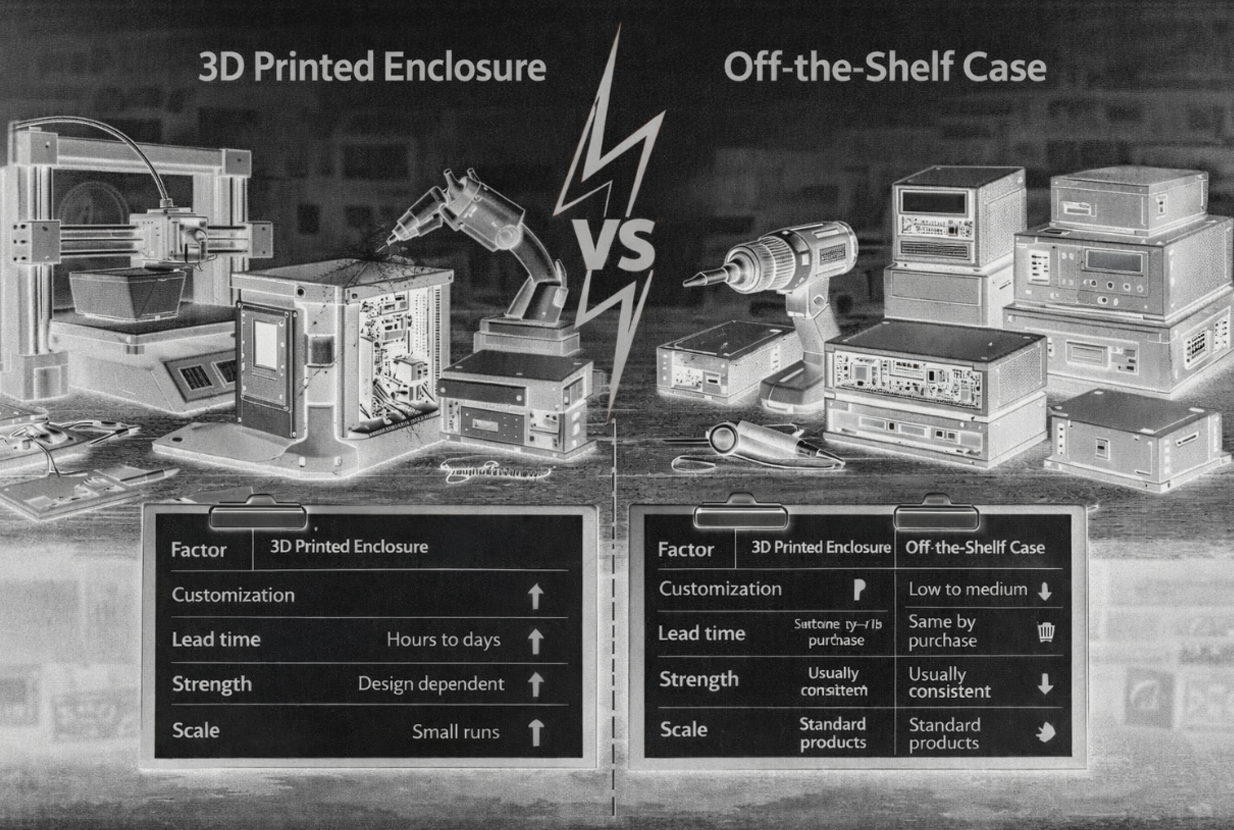

3D printed enclosures win on customization, while off-the-shelf cases win on immediate availability and consistent material ratings.

If your project uses standard board sizes and you can drill a few holes, a generic case is often fine.

If you need precise cutouts and internal standoffs, 3D printing is usually cleaner.

A hybrid approach is also common: print the body, then add a thin metal or acrylic panel for stiffness or shielding.

In hybrid builds that combine 3D printed enclosures with metal panels or reused housings, surface preparation becomes important, and tools like industrial laser cleaning machines are often used to remove coatings, oxidation, or residue before assembly.

Factor3D Printed EnclosureOff-the-Shelf Case

Customization High, Low to medium

Lead time: Hours to days Same day purchase

Strength Design dependent, usually consistent

Scale Small runs Standard products

Choosing the right enclosure follows three steps: define requirements, pick technology and material, then validate fit in real use.

A case that looks perfect in CAD can fail once you plug in cables, tighten screws, and run the electronics under load.

This how-to section includes three steps, and each step cuts reprints by forcing a quick check before you move on.

Define hardware constraints, including ports, batteries, and mounting points

Select a printing process and material that match the heat and handling

Test fit with real parts, then run a short heat and handling trial

Small DIY enclosures often cost about $1 to $10 in filament, while larger cases or specialty materials can cost $15 to $50.

Print services for resin or powder parts can cost more, especially with finishing.

Cost is driven by iteration and hardware.

One failed long print can cost more than several quick drafts.

Inserts, magnets, and gaskets add cost, but they can also prevent reprints and broken lids.

Electricity and wear parts can add a little too.

The fastest savings usually come from printing a quick fit coupon before committing to the full box.

Here are five factors that affect cost.

Material pricing and specialty filament choice

Part size and wall thickness

Complexity and print time

Post-processing, like inserts and sanding

Quantity and repeatability

The biggest mistakes are ignoring connector clearance, underbuilding fasteners, and forgetting heat management.

These errors show up as lids that will not close, ports that do not line up, and cases that soften or rattle.

Most mistakes are boring and preventable.

Designers forget finger space, cable bend space, and the real shape of plugs.

They rely on plastic threads in parts that will be opened weekly.

They add vents, but not airflow paths, so hot air still gets trapped.

They also skip strain relief, which causes normal handling to result in intermittent faults.

Tolerance drift is another trap, so test ports with real cables.

Size openings for real plugs and finger access

Reinforce screw bosses and avoid thin tabs in stress areas

Add strain relief so cables do not pull on solder joints

Plan airflow paths, not random vents

Avoid relying on plastic threads for repeated assembly

3D printed enclosures are ideal for sensor nodes, portable tools, robotics controllers, and custom interface devices.

They are also excellent for teaching builds, because a clean case makes the layout easier to understand.

The best use cases share one theme: the device shape is specific to your parts and environment.

That can mean a weird port layout, an odd mounting surface, or a project that must survive drops and vibration.

When you see that kind of constraint, custom printing becomes the simplest solution.

It is also a strong choice when you need a clean user interface, such as a labeled front panel.

Here are six applications, from common to specialized.

Sensor housings for air, temperature, and humidity boards

Portable testers and data loggers

Robotics electronics bays and cable organizers

Smart home wall devices and small gateways

Workshop fixtures and labeled interface panels

Rugged field devices for monitoring and control

A 3D printed enclosure is a protective shell that turns a circuit into a usable device.

Choose the enclosure type based on the environment and access, then match the printing technology and material to the heat and handling requirements.

Details like clearance, strain relief, and fastening strategy decide success.

Validate with real plugs and real load, then refine with quick drafts.