With the abundance of materials present in making our society functional, their quality and durability are inevitably crucial. Unfortunately, numerous solids have low surface energy, resulting in poor adhesive properties and reaction to moisture. Luckily, teams of experts have collectively been extending their efforts to improve these elements that make up our community. One of the advanced innovations contributing to developing most materials' quality is plasma surface treatment. It is a method used to modify exteriors, strengthen adhesion, and bond coatings. Furthermore, it prepares the object for its final processes by removing contaminants and increasing surface energy for better reactions, resulting in a sturdier product.

Plasma surface treatment increases the longevity and adhesive properties of materials significantly. These benefits are the most useful when considering home improvement. To better appreciate what this plasma etch technology and other processes can do for home innovation industry, read on.

Plasma surface treatment may sound like a highly invasive process. However, as its name suggests, it does not alter any other aspect of an object besides its exterior. Instead, it targets the outermost covering to be optimal for further processing. It does so by utilizing plasma to interact with the substances items are composed of. The form of matter consists of ions and electrons and is most similar to gas. Additionally, it has a negative and positive electric charge, which balances the component and makes it electrically neutral. The internal energy of plasma reacts with the surface's composition for plasma treatment to commence. Typically, this procedure has three effects:

Surfaces need to remain contaminant-free, especially when they are to be subjected to further processing. Plasma treatment effectively removes foreign substances to reveal a pristine exterior.

Various surfaces exhibit different properties and require a certain quality. For example, some items need to be liquid-repellant or have low friction. Curated treatment with plasma allows for this by modifying surfaces according to their standard.

Lastly, plasma treatment increases the energy of surfaces for better interactions with other elements. It does so by activation, reacting with the substances of certain exteriors to generate an ideal outermost covering.

Plasma treatments are performed in enclosures that are in a vacuum. Before any processes occur, the air within the chamber is pumped out by machines before any plasma can enter. Plasma treatment systems then allow gas to flow inside the chamber at low pressures before ionization occurs and there is an energy shift. Additionally, it is essential to remember that these procedures also happen in low temperatures to process heat-sensitive materials. Plasma treatment systems also come in a variety of forms. Two notable ones are plasma-enhanced chemical vapor deposition processes (PECVD) and physical vapor deposition (PVD). The first uses cold plasma at low deposition rates and temperatures. As for its applications, the procedure is widely used in creating anti-scratch layers and thin coatings for materials. Furthermore, its advantages lie in its uniformity, low power source, and being a more quality choice than its counterpart. It is also an easily manageable choice since its chambers are left more effortlessly clean, avoiding contamination. On the other hand, PVD is the process most utilized when it comes to generating plasma coat surfaces that improve longevity and increase the oxidation resistance of materials by depositing solid-state matter. Additionally, it contributes to hardness and durability. Therefore, these treatments are an efficient option for modifying exteriors.

One of the facets that can really benefit from plasma treatment systems is home improvement. Whether in the building stages or renovations, better quality materials are vital in developing an excellent abode. So, what role does plasma treatment play in home improvement?

Wood is a material that most houses, regardless of their motifs and architectural design, incorporate into their structure in one way or another. With that, it is advisable to consider wood modification to improve its overall application. Most of the time, traditional methods of plasma treatment, such as chemical or thermal, are used to optimize wood for use in construction. Moreover, these processes alter the surface of wood, allowing for changes in its mechanical properties that make it more suitable for home improvement. For example, it can make the material more water resistant, delaying long-term damage. In addition, it can make wood less susceptible to any inhabitants and organisms.

Water in nonideal circumstances can cause irreversible damage to one's home. To improve one's residence on that front, plasma technology can instill water-resistant or waterproof qualities in materials to make them more practical and last longer. On the same note, weak fixings can also impair a house's condition. To prevent this from happening, one must invest in stronger adhesives when repairing or building a component of the home. Luckily, plasma surface treatment works to modify surfaces and substances to exhibit both properties impeccably.

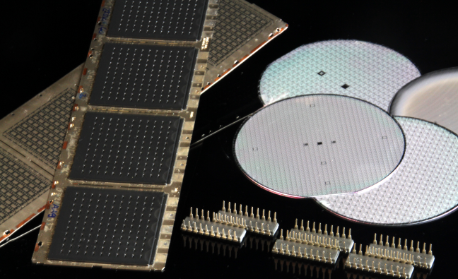

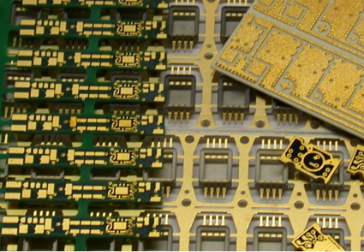

There is more to home improvement efforts than meets the eye. An often overlooked aspect of modifying one's place is the systems that make it operate behind the scenes. For example, plasma surface technology is highly used in electronics and semiconductors. This innovation makes our wirings and electrical components safe and functional.

Plasma surface treatment has a handful of contributions and applications in home improvement and other industries. However, we should also shed some light on this technology's more general advantages. Plasma treatment is a cost-efficient solution that is also excellent in economy, as it does not require large batches of heavy chemicals or harmful substances to be performed. In addition to its efficiency, it exhibits extreme precision, cutting costs by avoiding excess use. It is especially beneficial for industrial applications. Third on its list of advantages is that cold plasma is quintessential for surface treatment, specifically those that are heat-sensitive, such as polymers and plastics, which would make them easier to work with. This is because they have manageable and adjustable temperatures. Finally, this innovation is a flexible solution that is a prerequisite for multiple processes. Furthermore, it can fulfill several procedures simultaneously, reflecting its versatility and establishing itself as a multifunctional process.