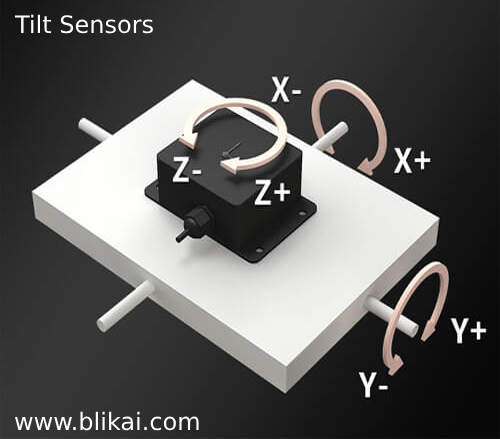

A tilt sensor is an instrument used to measure the tilt in multiple axes of a reference plane. Tilt sensors gauge the tilting position with reference to gravity and are utilized in various applications. They enable the easy detection of orientation or inclination. Similar to mercury switches, they are also known as tilt switches or rolling ball sensors. These instruments have become increasingly popular and are being adapted for a growing number of high-end applications. For instance, tilt sensors provide valuable information about both the vertical and horizontal inclination of an airplane, helping pilots understand how to navigate obstacles during flight. By knowing the plane's current orientation and the angle of inclination relative to the Earth's surface, stunt pilots, such as the Red Arrows, can perform impressive aerial displays. Tilt sensors are an essential decision-making tool for pilots.

The functionality of tilt sensors is influenced by factors such as gravity, vibration, temperature, zero offset, linearity, cross-axis sensitivity, acceleration/deceleration, shock, clear line of sight between the user and the measured point, and calibration of the sensors.

The key specifications of tilt sensors include:

Number of axes: The number of axes varies by application.

In robotics, a dual-axis tilt sensor is used.

In video game controllers and joysticks, a three-axis tilt sensor is required.

In some smartphones, four-axis sensors are used.

Resolution: The minimum inclination detected by the sensor.

Sensitivity: The sensor's ability to react to small changes.

Measuring range: The range of inclination that can be handled by the sensor. Some sensors measure up to 10°, while others cover up to 60°.

Noise tolerance: Noise can cause harmonic distortions in the sensor's function, leading to output variation and reduced system efficiency. Manufacturer's guidelines on noise levels should be followed.

Vibration: Vibrations can disrupt sensor functionality. Vibration resistance measures are necessary, especially in harsh conditions like off-road vehicles or construction sites.

The key benefits of tilt sensors include:

A tilt sensor contains a metallic ball that moves between two pins of the instrument, shifting the sensor from the 'on' to the 'off' position, and vice versa, when the sensor reaches a pre-determined angle. Tilt sensors are an environment-friendly alternative to mercury switches.

Tilt sensors have several key applications, including:

Tilt sensors function by detecting variations in the orientation of the conducting mass or fluid inside the sensor. This movement alters an electrical characteristic, such as capacitance or resistance, which can be measured and interpreted as the tilt angle.

The accuracy of a tilt sensor depends on its type and quality. However, typical readings range between ±0.1 and ±1 degrees.

Factors such as temperature variations, tremors, and improper installation can affect accuracy. Proper setup and calibration can help mitigate these impacts.

Calibration typically involves angling the sensor and adjusting the output to match these reference values. Some sensors come with an internal calibration process.

The tilt sensor should be securely fixed to the object whose tilt is being measured. The installation surface must be stable and free from vibrations. Proper alignment during installation is also crucial for accurate readings.

Power requirements vary depending on the type of sensor. The typical operating voltage range is 3.3V to 5V. It is essential to review the datasheet for precise specifications.

To test a tilt sensor, manually tilt it and observe changes in the output. Accuracy can be verified by comparing the output to a known reference angle.

Most tilt sensors are not affected by magnetic fields. However, it is important to check the specifications of the specific sensor being used, as some sensors, especially those with electrical components, may be susceptible to strong magnetic fields.