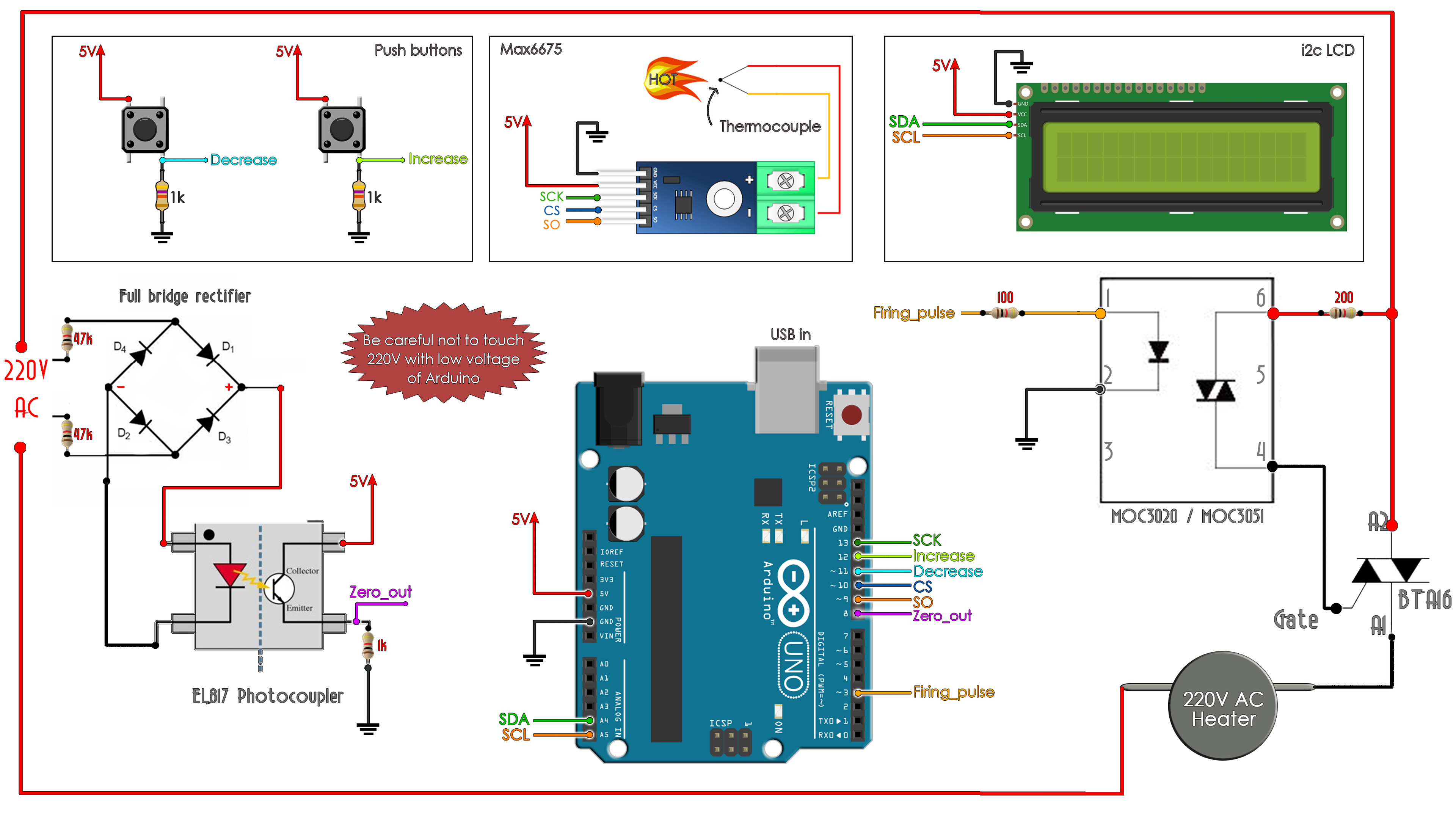

/* Max6675 Module ==> Arduino

* CS ==> D10

* SO ==> D9

* SCK ==> D13

* Vcc ==> Vcc (5v)

* Gnd ==> Gnd */

//LCD config

#include "max6675.h"

#include <Wire.h>

#include <LiquidCrystal_I2C.h>

LiquidCrystal_I2C lcd(0x27,20,4); //sometimes the adress is not 0x27. Change to 0x3f if it dosn't work.

/* i2c LCD Module ==> Arduino

* SCL ==> A5

* SDA ==> A4

* Vcc ==> Vcc (5v)

* Gnd ==> Gnd */

//Inputs and outputs

int firing_pin = 3;

int increase_pin = 11;

int decrease_pin = 12;

int zero_cross = 8;

int thermoDO = 9;

int thermoCS = 10;

int thermoCLK = 13;

//Start a MAX6675 communication with the selected pins

MAX6675 thermocouple(thermoCLK, thermoCS, thermoDO);

//Variables

int last_CH1_state = 0;

bool zero_cross_detected = false;

int firing_delay = 7400;

//////////////////////////////////////////////////////

int maximum_firing_delay = 7400;

/*Later in the code you will se that the maximum delay after the zero detection

* is 7400. Why? Well, we know that the 220V AC voltage has a frequency of around 50-60HZ so

* the period is between 20ms and 16ms, depending on the country. We control the firing

* delay each half period so each 10ms or 8 ms. To amke sure we wont pass thsoe 10ms, I've made tests

* and the 7400us or 7.4ms was a good value. Measure your frequency and chande that value later */

//////////////////////////////////////////////////////

unsigned long previousMillis = 0;

unsigned long currentMillis = 0;

int temp_read_Delay = 500;

int real_temperature = 0;

int setpoint = 100;

bool pressed_1 = false;

bool pressed_2 = false;

//PID variables

float PID_error = 0;

float previous_error = 0;

float elapsedTime, Time, timePrev;

int PID_value = 0;

//PID constants

int kp = 203; int ki= 7.2; int kd = 1.04;

int PID_p = 0; int PID_i = 0; int PID_d = 0;

void setup() {

//Define the pins

pinMode (firing_pin,OUTPUT);

pinMode (zero_cross,INPUT);

pinMode (increase_pin,INPUT);

pinMode (decrease_pin,INPUT);

PCICR |= (1 << PCIE0); //enable PCMSK0 scan

PCMSK0 |= (1 << PCINT0); //Set pin D8 (zero cross input) trigger an interrupt on state change.

PCMSK0 |= (1 << PCINT3); //Set pin D11 (increase button) trigger an interrupt on state change.

PCMSK0 |= (1 << PCINT4); //Set pin D12 (decrease button) trigger an interrupt on state change.

lcd.init(); //Start the LC communication

lcd.backlight(); //Turn on backlight for LCD

}

void loop() {

currentMillis = millis(); //Save the value of time before the loop

/* We create this if so we will read the temperature and change values each "temp_read_Delay"

* value. Change that value above iv you want. The MAX6675 read is slow. Tha will affect the

* PID control. I've tried reading the temp each 100ms but it didn't work. With 500ms worked ok.*/

if(currentMillis - previousMillis >= temp_read_Delay){

previousMillis += temp_read_Delay; //Increase the previous time for next loop

real_temperature = thermocouple.readCelsius(); //get the real temperature in Celsius degrees

PID_error = setpoint - real_temperature; //Calculate the pid ERROR

if(PID_error > 30) //integral constant will only affect errors below 30ºC

{PID_i = 0;}

PID_p = kp * PID_error; //Calculate the P value

PID_i = PID_i + (ki * PID_error); //Calculate the I value

timePrev = Time; // the previous time is stored before the actual time read

Time = millis(); // actual time read

elapsedTime = (Time - timePrev) / 1000;

PID_d = kd*((PID_error - previous_error)/elapsedTime); //Calculate the D value

PID_value = PID_p + PID_i + PID_d; //Calculate total PID value

//We define firing delay range between 0 and 7400. Read above why 7400!!!!!!!

if(PID_value < 0)

{ PID_value = 0; }

if(PID_value > 7400)

{ PID_value = 7400; }

//Printe the values on the LCD

lcd.clear();

lcd.setCursor(0,0);

lcd.print("Set: ");

lcd.setCursor(5,0);

lcd.print(setpoint);

lcd.setCursor(0,1);

lcd.print("Real temp: ");

lcd.setCursor(11,1);

lcd.print(real_temperature);

previous_error = PID_error; //Remember to store the previous error.

}

//If the zero cross interruption was detected we create the 100us firing pulse

if (zero_cross_detected)

{

delayMicroseconds(maximum_firing_delay - PID_value); //This delay controls the power

digitalWrite(firing_pin,HIGH);

delayMicroseconds(100);

digitalWrite(firing_pin,LOW);

zero_cross_detected = false;

}

}

//End of void loop

// |

// |

// |

// v

//See the interruption vector

//This is the interruption routine (pind D8(zero cross), D11(increase) and D12(decrease))

//----------------------------------------------

ISR(PCINT0_vect){

///////////////////////////////////////Input from optocoupler

if(PINB & B00000001){ //We make an AND with the state register, We verify if pin D8 is HIGH???

if(last_CH1_state == 0){ //If the last state was 0, then we have a state change...

zero_cross_detected = true; //We have detected a state change! We need both falling and rising edges

}

}

else if(last_CH1_state == 1){ //If pin 8 is LOW and the last state was HIGH then we have a state change

zero_cross_detected = true; //We haev detected a state change! We need both falling and rising edges.

last_CH1_state = 0; //Store the current state into the last state for the next loop

}

if(PINB & B00001000){ //We make an AND with the state register, We verify if pin D11 is HIGH???

if (!pressed_1)

{

setpoint = setpoint + 5; //Increase the temperature by 5. Change this with your value if you want.

delay(20);

pressed_1 = true;

}

}

else if (pressed_1)

{

pressed_1 = false;

}

if(PINB & B00010000){ //We make an AND with the state register, We verify if pin D12 is HIGH???

if (!pressed_2)

{

setpoint = setpoint - 5; //Decrease the temperature by 5. Change this with your value if you want.

delay(20);

pressed_2 = true;

}

}

else if (pressed_2)

{

pressed_2 = false;

}

}

//End of interruption vector for pins on port B: D8-D13