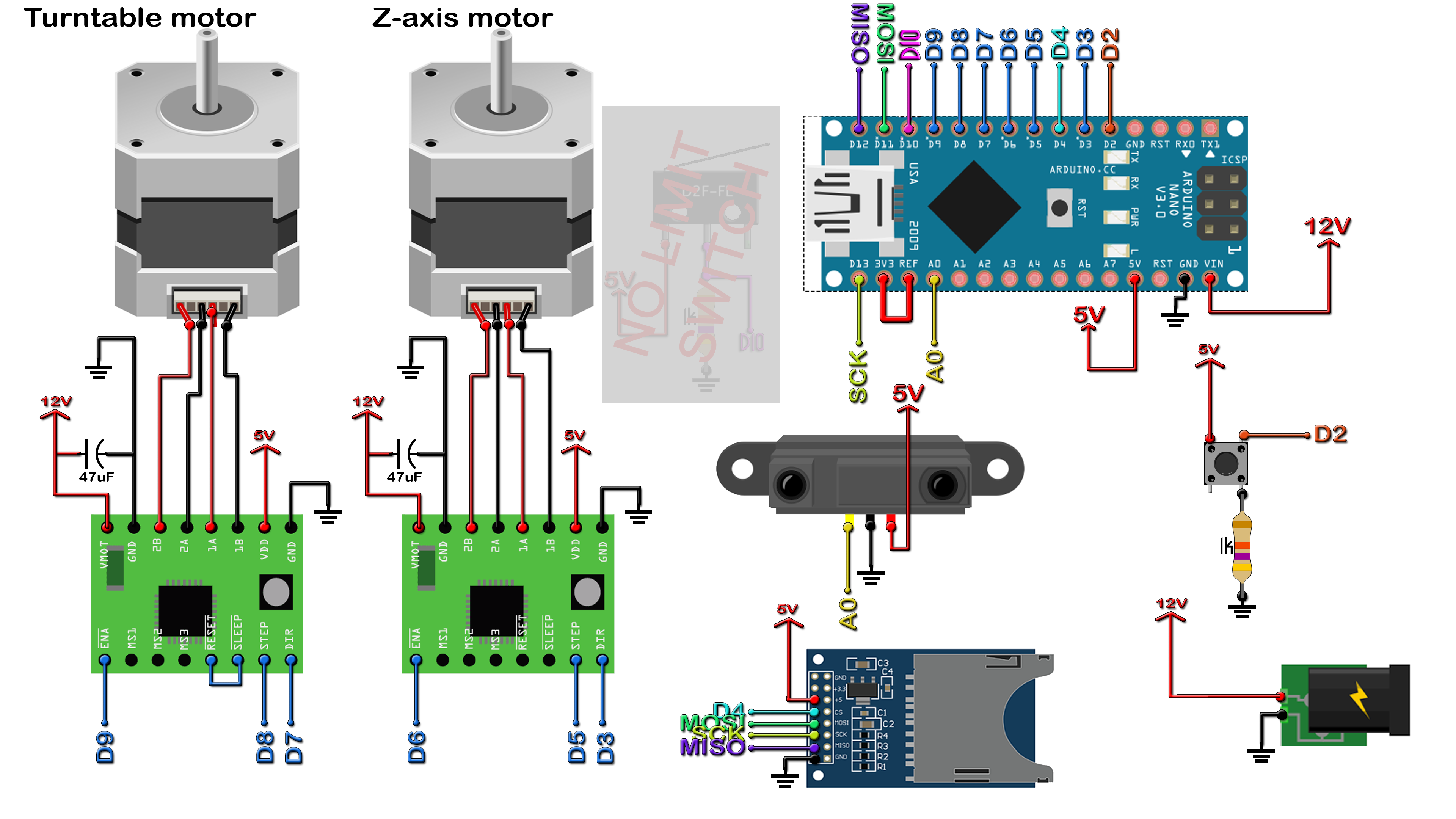

This code is for the schematic.

/*ELECTRONOOBS 3D scanner using IR sensor SHARP GP2Y0A51SK0F;

Datasheet GP2Y0A51SK0F: https://www.pololu.com/file/0J845/GP2Y0A41SK0F.pdf.pdf

Tutorial: http://www.electronoobs.com/eng_arduino_tut30.php

YouTube Channel: https://www.youtube.com/channel/UCjiVhIvGmRZixSzupD0sS9Q

SUBSCRIBE!

Schematic: http://www.electronoobs.com/eng_arduino_tut30_sch1.php

*/

#include <SPI.h>

#include <SD.h>

//Editable variables

int scan_amount = 40; //Amaunt of scans for each point. The result is the mean. This would increase the delay for each scan.

String file="scan_001.txt"; //Name of the saved file on the SD card

int z_axis_height = 12; //in cm //Maximum height of the scaned file

int step_delay = 3000; //in us //Delay for each step for the stepper motor in microseconds

float z_layer_height = 0.5; //in mm //Layer height. The amount of mm for each layer.

int lead_screw_rotations_per_cm = 8; //How many rotations needs the lead screw to make in order to make 1cm.

int steps_per_rotation_for_motor = 200; //Steps that the motor needs for a full rotation.

int distance_to_center = 8; //In cm. Distance from sensor to the turntable center in cm

//I/O

int button = 2;

int limit_switch = 10;

//Turntable driver pins

int dir_r = 7;

int step_r = 8;

int enable_r = 9;

//Z-axis driver pins

int dir_z = 3;

int step_z = 5;

int enable_z = 6;

//Variables

File file_values; //Used for the SD card module

int scan = 0; //Activate/deactivate scanning

int scan_changed = 0; //Scan process was changed

float distance = 0; //Measured distance

float angle = 0; //Rotation angle for each loop (0º-360º)

float x = 0; //X, Y and Z coordinate

float y = 0;

float z = 0;

int z_loop = 0; //variable used for the z-axis motor rotation

int r_loop = 0; //variable used for the turntable motor rotation

float measured_analog = 0; //Analog read from the distance sensor

float analog = 0; //Analog MEAN

float RADIANS = 0.0; //Angle in radians. We calculate this value later in Setup loop

int steps_z_height = 0; //Variable used for the amount of steps in z-axis

int homed = 0;

void setup() {

Serial.begin(9600);

pinMode(A0, INPUT);

pinMode(limit_switch, INPUT);

pinMode(button, INPUT);

analogReference(INTERNAL);

SD.begin(4);

pinMode(dir_z, OUTPUT);

pinMode(step_z, OUTPUT);

pinMode(enable_z, OUTPUT);

pinMode(dir_r, OUTPUT);

pinMode(step_r, OUTPUT);

pinMode(enable_r, OUTPUT);

digitalWrite(enable_z,HIGH);//disable the z_azis driver

digitalWrite(enable_r,HIGH);//disable the z_azis driver

//Calculate variables

RADIANS = (3.141592 / 180.0) * (360/steps_per_rotation_for_motor);

steps_z_height = (z_layer_height * steps_per_rotation_for_motor * lead_screw_rotations_per_cm)/10;

/*UNCOMENT this if using limit swithc connected to D10

while(!digitalRead(limit_switch) && homed == 0)

{

digitalWrite(enable_z,LOW); //enable the z_azis driver

digitalWrite(dir_z,HIGH); //z_azis spin to left (lowering z-axis)

digitalWrite(step_z,HIGH); //z_azis make a step

delayMicroseconds(step_delay);

digitalWrite(step_z,LOW);

delayMicroseconds(step_delay);

}

homed = 1;*/

}

void loop() {

//Wait till the push button is pressed

if(digitalRead(button))

{

if(scan == 1 && scan_changed == 0)

{

scan=0;

delay(3000);

scan_changed=1;

}

if(scan == 0 && scan_changed == 0)

{

scan=1;

delay(3000);

scan_changed=1;

}

scan_changed = 0;

}

//If the scanning proces is ON

if(scan == 1)

{

//We stop when we reach the maximum height

if(z < z_axis_height)

{

for(int loop_cont = 0 ; loop_cont < steps_per_rotation_for_motor; loop_cont++)

{

getDistance();

digitalWrite(enable_r,LOW); //enable the turntable driver

digitalWrite(dir_r,LOW); //turntable spin to right

digitalWrite(step_r,HIGH); //make a step

delayMicroseconds(step_delay);

digitalWrite(step_r,LOW);

delayMicroseconds(step_delay);

angle = angle + RADIANS; //Increase the angle by one more unit

write_to_SD(x,y,z); //Write x, y, z files to SD card function

//Uncomment this for Serial debug

/*

Serial.print(loop_cont); Serial.print(" ");

Serial.print(angle); Serial.print(" ");

Serial.print(distance); Serial.print(" ");

Serial.print(x); Serial.print(" ");

Serial.print(y); Serial.print(" ");

Serial.print(z); Serial.println(" "); */

}

angle = 0; //Reset the angle value for next rotation

/*My threaded rod needs 8 full rotations for 1cm. A full rotation is 200 steps in my case.

We need 1600 for 1cm. So, we need 80 for 0.5mm. The amount is calulated automaically.

Just change the variables at the beginning if you want*/

while(z_loop < steps_z_height)

{

digitalWrite(enable_z,LOW); //enable the z_azis driver

digitalWrite(dir_z,LOW); //z_azis spin to right

digitalWrite(step_z,HIGH); //z_azis make a step

delayMicroseconds(step_delay);

digitalWrite(step_z,LOW);

delayMicroseconds(step_delay);

z_loop = z_loop+1; //Increase the loop by 1

}

z = z + z_layer_height; //Increase the made z-height by 1 unit

z_loop = 0; //Reset the z-axis rotation variable

}//end of if z_height

//We finished the scan, we stop the drivers

else

{

digitalWrite(enable_z,HIGH);

digitalWrite(enable_r,HIGH);

}

}//if scan

}//End ov void loop

//Function that gets the distance from sensor

double getDistance()

{

for (int aa=0; aa < scan_amount; aa++)

{

measured_analog= analogRead(A0);

delay(2);

analog = analog + measured_analog;

}

distance = analog/scan_amount; //Get the mean. Divide the scan by the amount of scans.

analog=0;//reset the andlog read total value

measured_analog = 0; //reset the andlog read value

distance = mapFloat(distance,0.0,1023.0,0.0,3.3); //Convert analog pin reading to voltage

distance = -5.40274*pow(distance,3)+28.4823*pow(distance,2)-49.7115*distance+31.3444; //From datasheet

distance = distance_to_center - distance; //the distance d = distance from sensor to center - measured distance

y = (cos(angle) * distance);

x = (sin(angle) * distance);

/*//For debug

* Serial.print(distance); Serial.print(" ");

Serial.print(x); Serial.print(" ");

Serial.print(y); Serial.print(" ");

Serial.print(z); Serial.print(" ");

Serial.print(angle); Serial.println(" "); */

}

//Function that maps the value in a float format

float mapFloat(float fval, float val_in_min, float val_in_max, float val_out_min, float val_out_max)

{

return (fval - val_in_min) * (val_out_max - val_out_min) / (val_in_max - val_in_min) + val_out_min;

}

//Function that writes the value to the SD card

void write_to_SD(float SDx, float SDy, float SDz)

{

file_values = SD.open(file, FILE_WRITE);

if (file_values)

{

file_values.print(SDx); file_values.print(",");

file_values.print(SDy); file_values.print(",");

file_values.println(SDz);

file_values.close();

}

}