Arguably, the most tedious part of any Tesla coil build is winding the transformer. Getting that fine wire wound onto a suitable form, making everything neat, and making sure it’s electrically and mechanically sound can be tricky, and it’s a make-or-break proposition, both in terms of the function and the aesthetics of the final product. So this high-output printed circuit Tesla should take away some of that tedium and uncertainty. Now, PCB coils are nothing new — we’ve seen plenty of examples used for everything from motors to speakers. We’ve even seen a few PCB Tesla coils, but as [Ray Ring] points out, these have mostly been lower-output coils that fail to bring the heat, as it were.

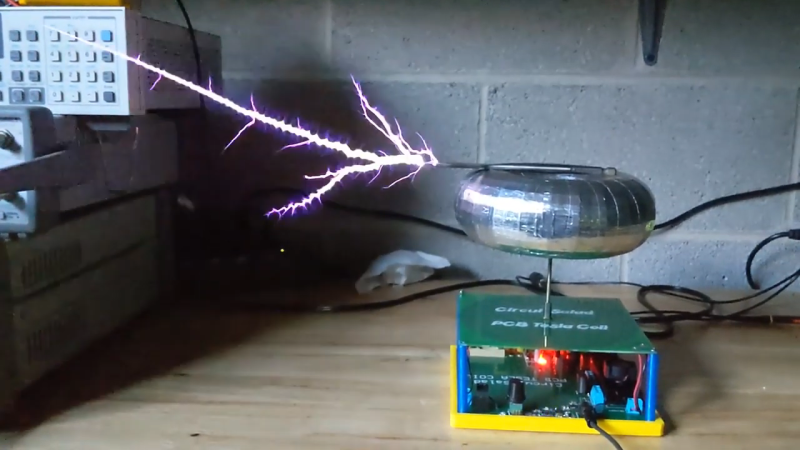

His printed coil generates some pretty serious streamers — a foot long (30 cm) in some cases. The secondary of the coil has 6-mil traces spaced 6 mils apart, for a total of 240 turns. The primary is a single 240-mil trace on the other side of the board, and the whole thing is potted in a clear, two-part epoxy resin to prevent arcing. Driven by the non-resonant half-bridge driver living on the PCB below it, the coil can really pack a punch. A complete schematic and build info can be found in the link above, while the video below shows off just what it can do.

Honestly, for the amount of work the PCB coil saves, we’re tempted to give this a try. It might not have the classic good looks of a hand-wound coil, but it certainly gets the job done.

Bret Tschacher says:

June 9, 2021 at 7:26 am

I doubt this would be a problem most of the time as metal cases are/or should be grounded, which would be the same as a faraday cage in this case. Plastic cases would be a different issue but then the arc wouldn’t be drawn to that unless there was something or some place in the case the arc could go to or through, which would obviously be metal or in some cases carbon and it would likely need to be connected to a drain/ground. Still it would be prudent to not be doing this. May I suggest holding something metal in your hand while standing in water or holding a metal pipe connected to ground instead? Also notice how many times the word ‘case’ is used here. It seems to me the use of a ‘case’ around the primary part of the circuit would also be a good idea in case the HV output were to arc to that part of the circuit thereby basically cooking the Tesla circuit. In case anyone is curious as I am in this case, how many volts does one of these produce to make an arc travel this far? I have seen around 50kv go as far as 1 to 1-1/2 in. working around ignition coils for late model cars