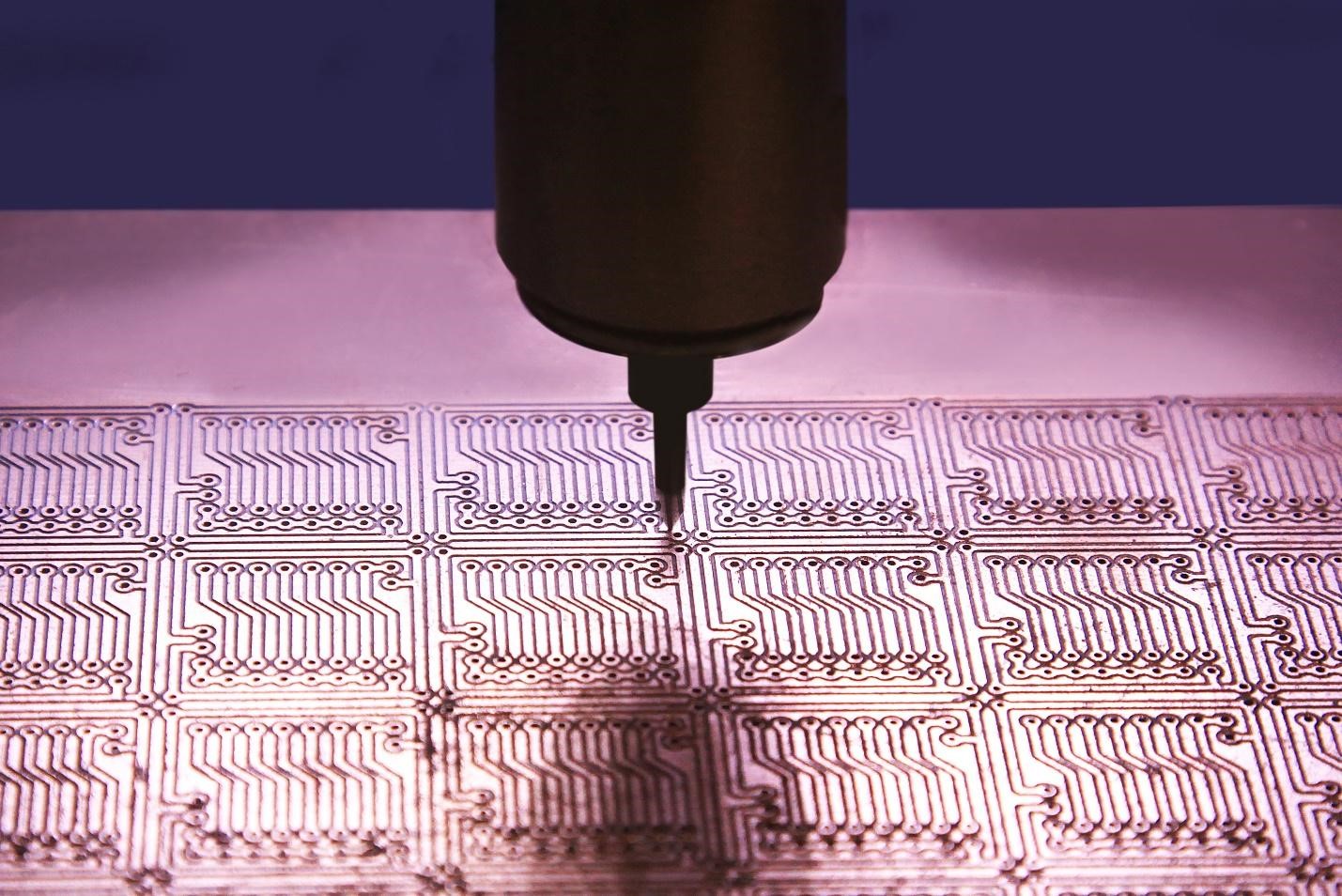

The world is dynamic, and so is the business’s need and scenario, making it very crucial to save time. We all know that “Time is Money,” but in today’s time, the saying has changed a bit, “Time is not only Money, but it is also Gold!” Thus, it becomes very vital to have a quick turn PCB assembly. Having a quick turn PCB, you can make sure that your customer has their printed circuit board faster than ever. PCB gives a very convenient platform wherever electric components are linked with electric wirings to operate any device. Quick turn PCB are in great demand over the last few years to keep the business pace and confronting challenging deadlines and persistent schedules. The whole concept of quick turn PCB relies on the PCB assembly before the fabrication process. As PCB manufacturers, one should understand why their customers need PCB manufacturing.

Below are some Reasons Why you Should Select Quick Turn PCB Assembly.

Why is it beneficial for you to pick a leading firm while choosing a quick-turn PCB?

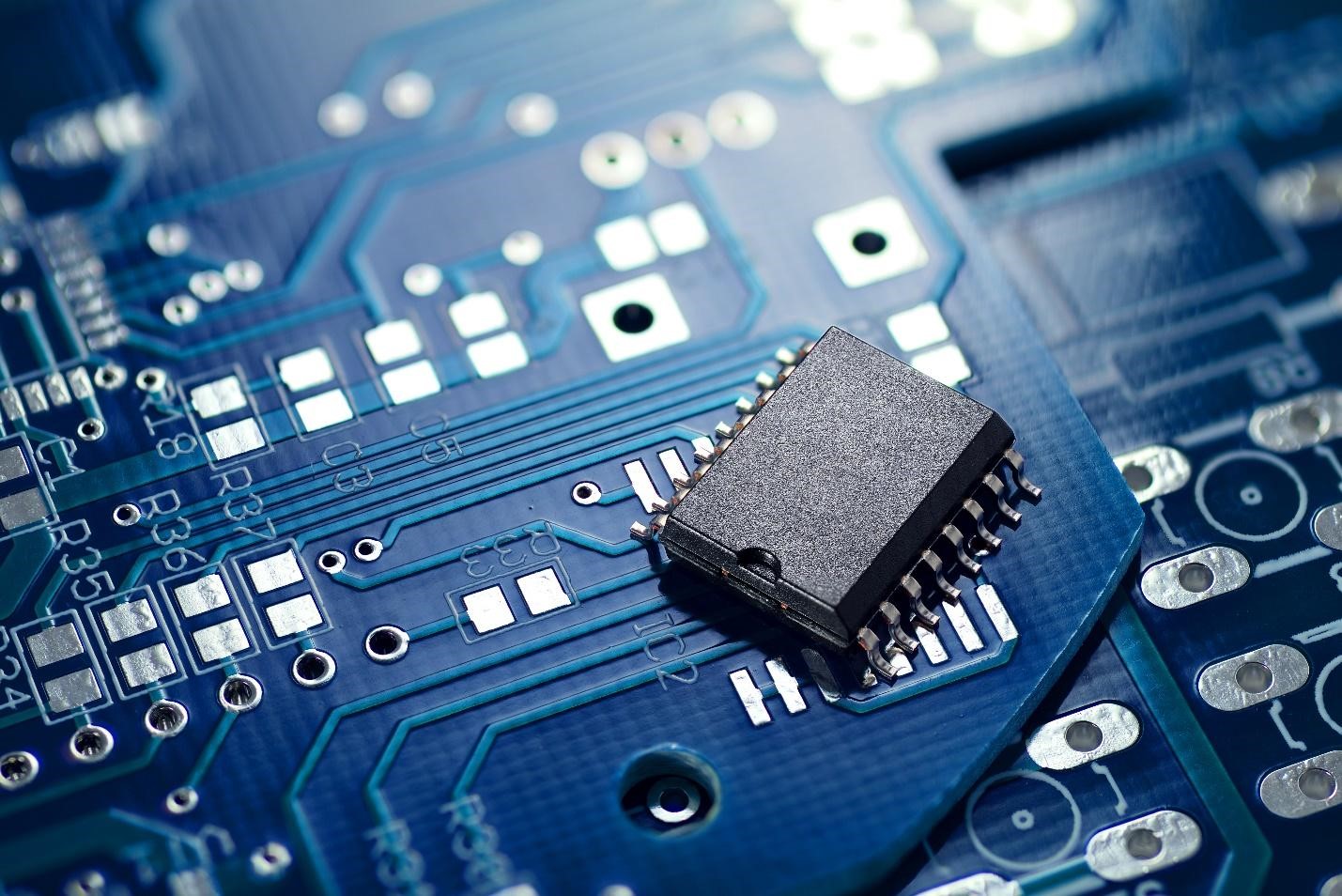

Manufacturing PCB requirements for their own self is quite a daunting task as it requires specialized equipment and human resources to work for the specific task. And with the pandemic, it is even more difficult to invest in a huge amount, especially if the company needs a small production run. This is when PCB manufacturers come into the picture. PCB manufacturers provide an apt and timely solution for your PCB necessities. Experienced manufacturers can provide you with a wide variety of deals and packages to meet the product quality, size of PCB, type of tooling, and urgency of the project.

Another top advantage of quick turn PCB is that customers do not need to waste time, and looking out for the most suitable option as experienced manufacture can suggest you the best and optimum quick turn PCB for your business needs. You can even have a customized package specially designed for your business. They can offer different shapes of quick turn PCBs such as round, rectangular, hexagonal, etc.

Last but not least, it is very important to select a PCB manufacturing firm that will provide clients with code-compliant PCBs that will obey codes like ISO, UL, RoHS, and so on. To make the long story short, quick turn PCB saves a lot of your money and time. It saves time for both the parties involved, i.e., manufacturer and PCB shopper. It also reduces delay as a quick turn PCB ensures that the customer does not have to wait quite as long for the desired PCB. The ultimate solution to all your PCB needs and problems is getting in touch with an experienced and leading PCB manufacturer.

PCB Assembly allows companies of all sizes to boost their output cycle while lowering production time and costs to satisfy all manufacturing sizes’ demands and specifications under strict deadlines. It also collaborates with the developers and project managers to guarantee that the final design specifications are fulfilled by:

Properly inspecting your instructions and supplies: To produce accurate and consistent performance, a Quick-Turn PCB assembly will review their customer’s instructions and materials. Clear instructions from customers would finish the work without any delays. PCB specialists would best provide PCB specification analysis and manufacturing flexibility evaluations to achieve total effectiveness and reduce rework risk.

Supporting with stock selection: Getting the right product at the right time will help the customers shorten the manufacturing period and save money. Budgetary predictions help them make cost-effective decisions.

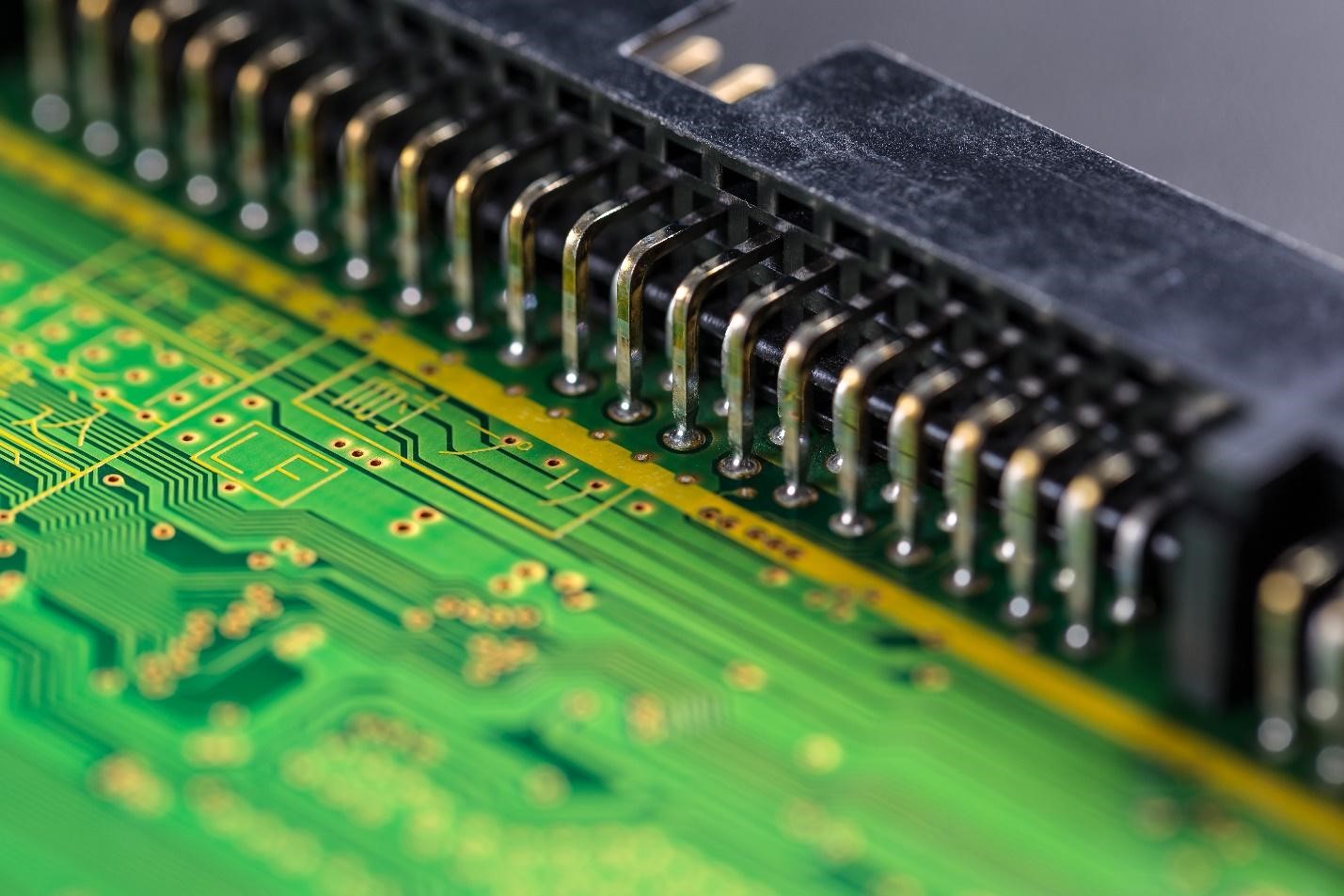

Strict screening and monitoring protocols: Any PCB Assembly’s long-term customer partnerships are built on high-quality materials. Extensive checking at all stages of the product production process helps in improving performance efficiency and accuracy. Working with the proper fast change PCB assembly manufacturer will save your customers time and money.

Reduce the promotion time and expense to market: PCB prototype assembly process tends to follow the best guidelines as a complete turnkey manufacturing PCB services. The strategy aims to help your customer gain market feasibility with reduced manufacturing time and expense, from the original concept and development analysis to the procurement and purchase of the best components, sample installation, and testing.

Automated vs. manual PCB Assembly: PCB Assembly experts will advise your customers on one of the most cost-effective methods for designing the product. You may rely on reputed PCB companies to ease the complicated logistics and practice of product creation through manufacturing with turnkey assembly services that manage the whole flex circuit or printed circuit production process.

The prototype design-engineering experts will address the benefits and drawbacks of automatic versus manual PCB assembly to help you make profitable decisions and minimize rework.

Author Bio:

Laura Stevens works as a digital marketing manager at PCBGOGO. PCBGOGO manufactures high-quality PCBs and provides the best PCB assembly services that are affordable and effective. In her free time, she writes informational blogs and articles that aim at helping people.

Website: https://www.pcbgogo.com/