DC non invasive current clamp for oscilloscope DIY

3.0 DC current clamp compensation coil

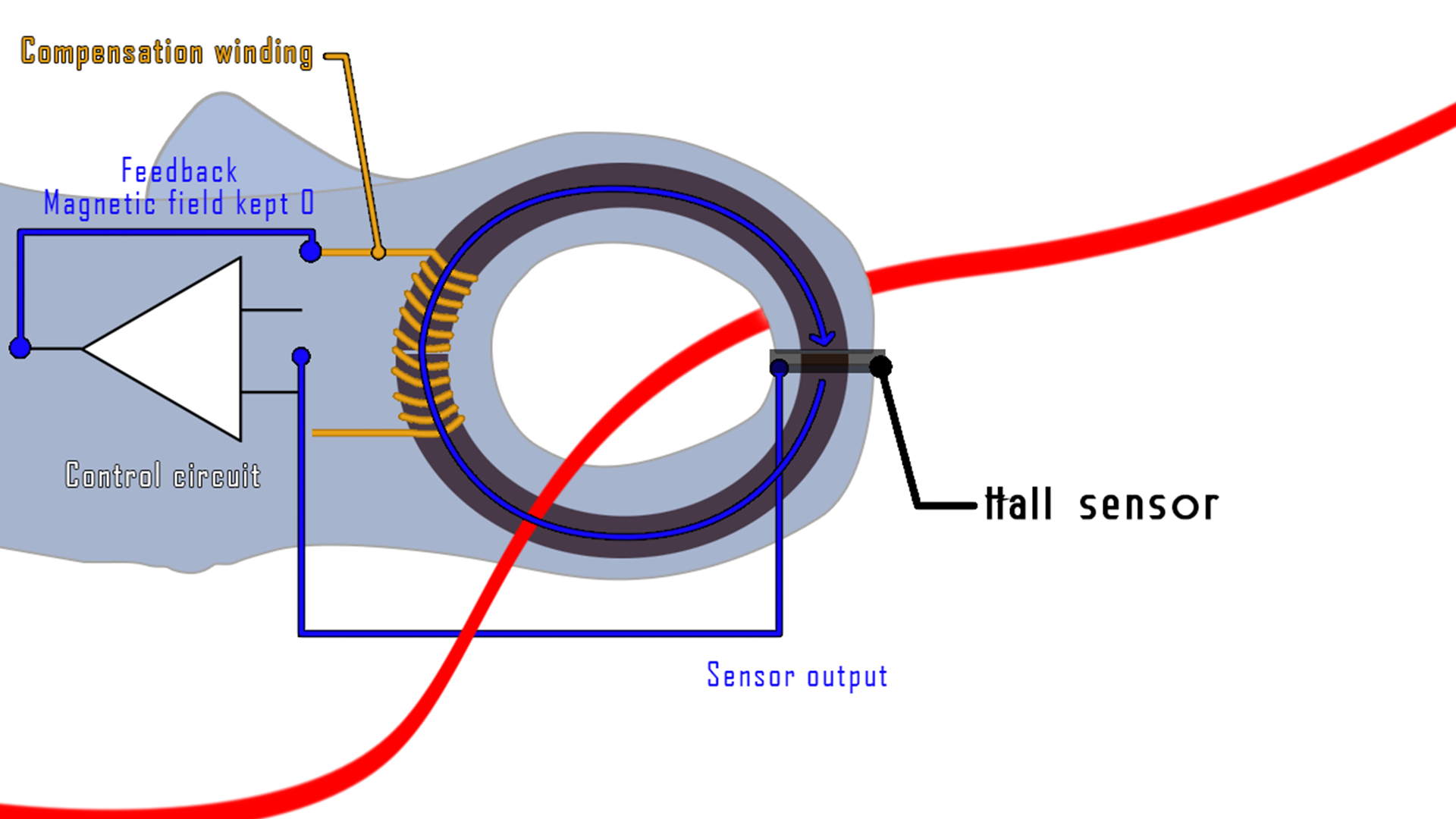

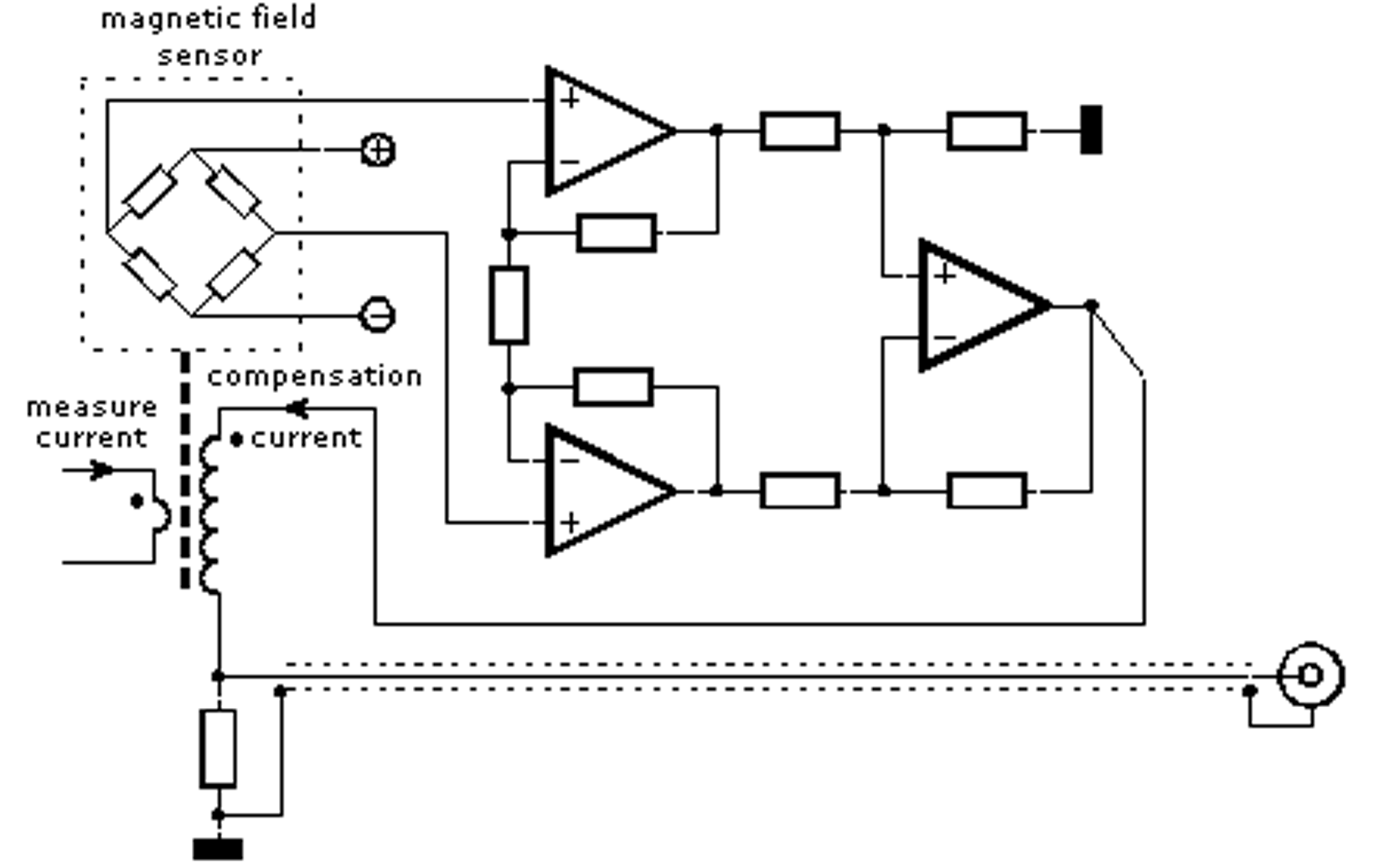

Another way and a better way to measure DC current is with a compensation winding. But that’s a little bit more difficult to mount and calibrate. But its principle goes like this.

The primary winding it is also the measured current carrying wire and is inserted through the core opening. There is also a secondary winding, but now it functions as a compensation coil. The core is provided with an air gap that holds a sensor, once again a hall-sensor, which measures the magnetic flux in the core.

The current in the primary wire will magnetize the core. This magnetic field is measured with the sensor and as a result of this, the control circuit runs a current through the compensation winding in a way that the magnetic flux in the core is kept zero. As a result of this, the core will never be magnetized. The advantage is that the non-linear properties and hysteresis of both the core and the magnetic sensor have little influence on the measurement results.

About me

About me  History

History  Let's learn

Let's learn  Contact us

Contact us  Arduino tutorials

Arduino tutorials Circuits tutorials

Circuits tutorials  Robotics tutorials

Robotics tutorials Q&A

Q&A Blog

Blog  Arduino

Arduino  Circuits

Circuits Robotics

Robotics  Modules

Modules  Gadgets

Gadgets  Printers

Printers  Materials

Materials  3D objects

3D objects  3D edit

3D edit  Donate

Donate  Reviews

Reviews  Advertising

Advertising