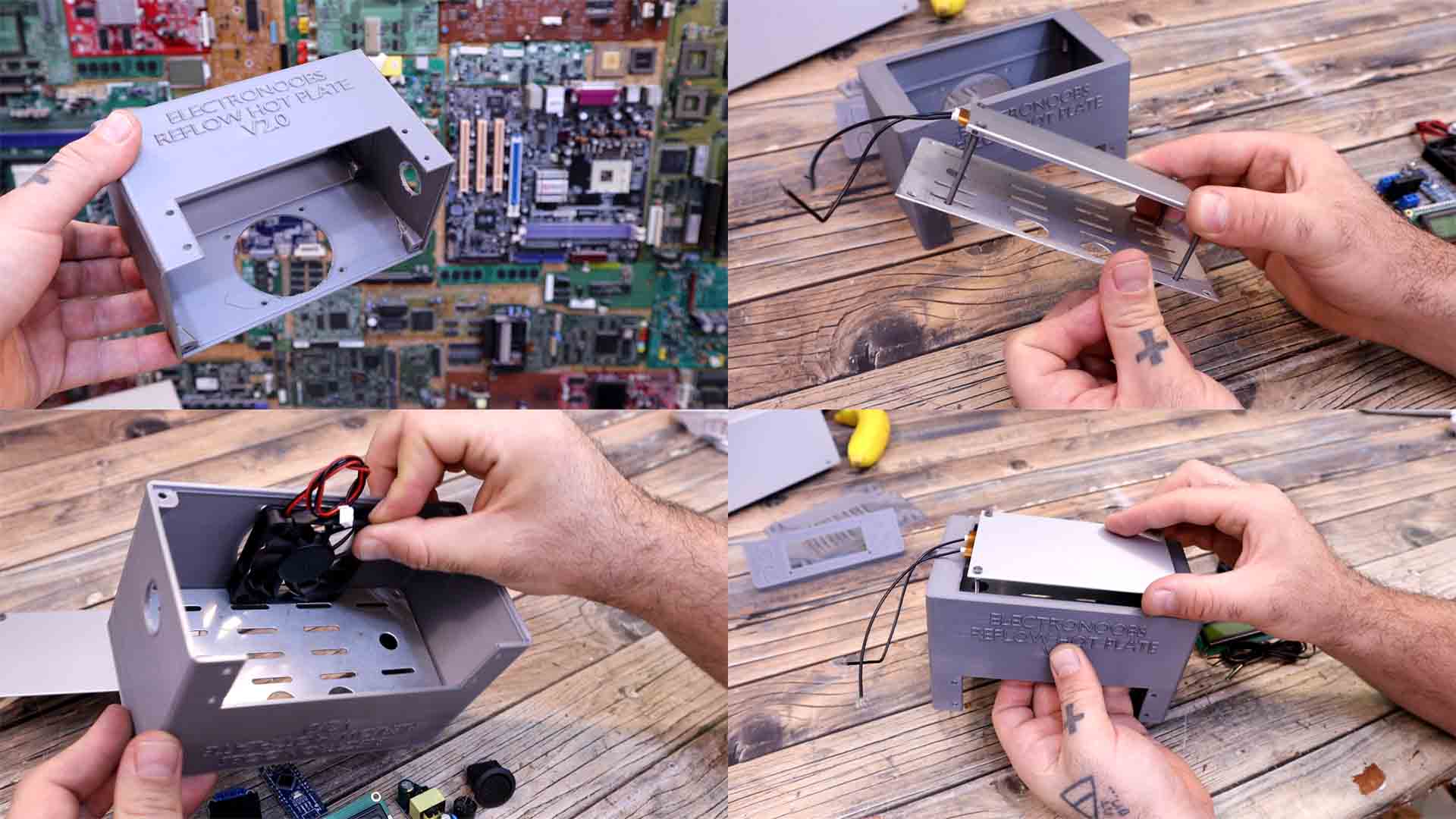

I’ve made my case design out of plastic. This was printed in ABS so it will withstand more heat and I was using 0.4mm nozzle and 0.25mm layer height with 3 periemters and 20% infill. The heating plate will stay on the top hole and it will never be in direct contact with the case. Also, the only way to transfer heat to the plastic case would be thought some screws that we add below the plate. And because they are long enough, the heat will transfer slowly. Even more, these screws will be connected to a metal plate I’ve told you before and only this plate will be in contact with the case. This plate will dissipate the heat even more and below we will have a cooling fan. Between the heating plate and the metal plate I also want to put some heat insulation cotton. This should protect the case even more from the heat of the top plate. And above all that, remember that our solder paste melting point is 172 degrees and you could also find some paste that will melt at 138. This temperature is still ok with ABS that melts at around 230 degrees or more.