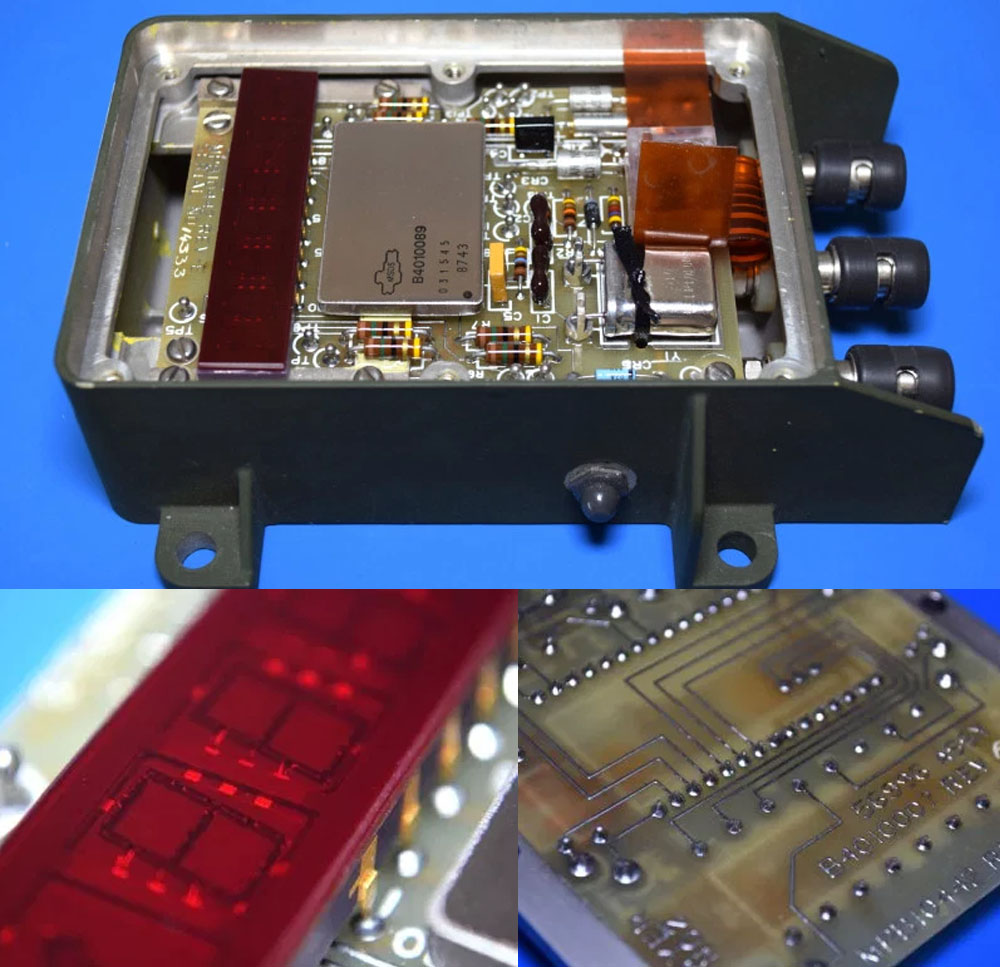

In the end, I tapped the holes in the front panel so that it would grip on screws that are slightly larger than the original ones. Threaded into the 8 mm thick panel, these screws gave me something to put some leverage on. With considerable force, I eventually broke the seal that was holding the two pieces together. While I don’t like to make any permanent alterations to the military hardware out of respect for the history involved, once the original screws are back in place you can’t tell the holes have been enlarged. See

full post here.

Apart this post, if you have your own project and you need good quality PCBs, consider using the services of JLCPCB.com which will offer you quite good services, I use their services a lot of my PCBs.

Consider supporting ELECTRONOOBS on PATREEON.